No products in the cart.

Return To ShopBest Kitchen Cabinet Materials: A Homeowner’s Guide

When it comes to the quality of a cabinet, the material is key. On the U.S. market today, cabinets are generally made from five types of materials: Solid Wood, Plywood, MDF, HDF, and Particle Board. Chances are, before reading this, you’ve already come across many of these terms, or heard names like Laminate cabinets, Hardwood cabinets, Oak cabinets, Thermofoil cabinets, or Veneer cabinets.

Strictly speaking, Laminate, Thermofoil, and Veneer aren’t “materials” in the way most people think—they’re more of a manufacturing technique. Like Paint or Stain, they fall under Surface Finishes. For simplicity, I like to categorize cabinet materials into three main groups: Solid Wood, Engineered Wood, and Surface Finishes.

I’ve noticed that many people aren’t fully familiar with cabinet materials, so I believe it’s important to give a brief overview—so that when you shop for cabinets, you can make an informed choice and get the best quality.

Table of Contents

Solid Wood

Solid wood can be divided into Hardwood and Softwood.

Hardwood

Common hardwoods include Oak, Maple, Cherry, Walnut, Birch, all of which come from broadleaf deciduous trees. These woods are dense, scratch-resistant, and can be either stained or left with their natural grain. They are more durable and stable than softwoods, making them less prone to warping.

The downside? Hardwood is harder to work with, more expensive, and heavier—making it more labor-intensive to transport and handle. It’s commonly used for high-end cabinet doors, solid wood frames, and stained wood-grain cabinets. Cabinets made from hardwood feature beautiful grain patterns, exude a premium feel, and have a long lifespan.

If your household values a natural wood look and wants a high-end, custom kitchen, hardwood is an excellent choice.

Softwood

Softwoods come from coniferous evergreen trees, such as Pine, Fir, and Spruce. Compared to hardwood, softwoods are lighter and easier to work with, with noticeable grain patterns. However, they are prone to dents and scratches, sensitive to moisture, and generally less visually appealing than hardwoods.

Softwood is usually best suited for budget-friendly kitchens, temporary installations, rental properties, or DIY enthusiasts who enjoy working with wood themselves.

Hardwood vs Softwood

| Feature | Hardwood | Softwood |

|---|---|---|

| Source Trees | Broadleaf (Oak, Maple, Cherry, Walnut, Birch) | Coniferous (Pine, Fir, Spruce) |

| Density | High, very hard | Low, soft |

| Durability | Extremely durable | Easily dented/scratched |

| Impact Resistance | Strong | Weak |

| Warp Resistance | Resists warping | Sensitive to humidity |

| Grain / Visual | Fine, natural, high-end look | Coarse, rustic/country style |

| Stainability | Excellent, even color | Limited, uneven |

| Weight | Heavy | Light |

| Cost | High | Budget-friendly |

| Cabinet Use | Shaker door frames, solid wood doors, high-end custom | RTA, low-budget, interior frames |

| Lifespan | 10–30+ years | 3–10 years |

| Environmental | Slow-growing, less abundant | Fast-growing, sustainable |

Engineered Wood

Engineered wood is a very common material in cabinets, furniture, and construction. Unlike solid wood, it isn’t made from a single, natural piece of timber. Instead, it’s created by pressing and gluing together multiple layers of wood, fibers, or particles under heat, resulting in a material with high stability. Common types include Plywood, MDF, HDF, and Particle Board.

Plywood

Plywood is made by layering thin sheets of wood veneer in alternating directions, bonding them with glue, and pressing them into a solid, sturdy panel. Each layer is called a “ply”—so you might see 3-ply, 5-ply, or 11-ply panels. 11-ply plywood is commonly used in high-quality kitchen cabinets.

This cross-layered structure greatly enhances the panel’s stability. It effectively resists expansion, contraction, warping, or deformation caused by changes in humidity and temperature. In the U.S. cabinet industry, plywood is considered the best choice for cabinet boxes, shelves, and backs due to its combination of lightweight, stability, and durability. Compared to solid wood, it’s less prone to cracking or warping from environmental changes; compared to MDF and other engineered boards, it offers better structural strength and screw-holding power.

Plywood’s excellent load-bearing capacity and stability make it the go-to material for kitchen cabinets. From a cost perspective, plywood is typically mid-range—more expensive than MDF or particle board, but far less costly than using solid wood panels throughout. On the U.S. market, the highest-quality cabinets almost always use plywood for cabinet boxes, shelves, and backs, making it a high value-for-money choice.

MDF

MDF (Medium-Density Fiberboard) is made by mixing wood fibers with glue and compressing them under high heat and pressure. Unlike plywood, it isn’t made from layered wood veneers, and unlike solid wood, it isn’t a single solid piece—it’s engineered by breaking down wood into fibers and then re-compressing them. Its density is lower than HDF but higher than particle board.

What are wood fibers? They’re basically wood chips pulverized into fine powder.

MDF has a very smooth, flat surface, without prominent wood grain like solid wood. It’s resistant to cracking and warping, and it’s more affordable than solid wood. For these reasons, many cabinet manufacturers use MDF as the center panel for painted Slab doors or Shaker doors.

HDF

HDF (High-Density Fiberboard) is essentially an upgraded version of MDF—denser, harder, and more durable. Its structure and manufacturing process are similar to MDF, but it’s more compact and stronger.

HDF is a high-quality material: it has higher density, greater durability, and a smoother surface that’s ideal for painting or laminating. It resists dents and scratches better, absorbs less moisture, and is more stable against warping compared to MDF. Because of its stability, HDF is perfect for cabinet door center panels.

Like all materials, it has trade-offs: HDF is more expensive and heavier than MDF, and its water resistance is still lower than plywood.

MDF vs HDF

| Feature | MDF | HDF |

|---|---|---|

| Pros | Smooth surface, ideal for painted doorsStable, resists warpingCost-effective, easy to work | Denser & strongerSuperior impact & warp resistanceExcellent screw-holding strengthPerfect for premium paint finishes |

| Cons | Moderate moisture resistanceEdges absorb water if unsealedWeaker under heavy load | Higher costHarder to cut, heavierLess common, fewer manufacturers |

| Cabinet Use | Painted Shaker/slab doors, trim, decorative panels | High-end painted doors, high-strength panels, premium furniture |

Why MDF is More Common Than HDF for Painted Shaker Cabinet Doors in the U.S. You might wonder: if HDF is so much better than MDF, why do most U.S. cabinets still use MDF for painted Shaker doors? There are six main reasons why HDF isn’t widely adopted.

6 Reasons HDF Is Not Used

1. HDF is more expensive

HDF’s higher density requires more wood fibers, greater pressure, and longer pressing time. This drives up production costs compared to MDF. Cabinet doors cover large surface areas, so using HDF instead of MDF could increase material costs by 20–40%. Most U.S. brands need to control costs for their dealer networks, so HDF isn’t commonly used.

2. No need to upgrade

In the U.S. cabinet industry, there’s a general consensus that MDF already performs well enough for painted Shaker doors. MDF provides a smooth, paint-ready surface, resists cracking better than solid wood, and keeps costs manageable. From a manufacturer’s perspective, switching to HDF is an unnecessary performance “upgrade”—like upgrading an iPhone 13 to an iPhone 17 when the older model already does everything needed.

3. Higher shipping costs

Cabinet manufacturing is heavily logistics-driven. HDF is 15–25% heavier than MDF, which increases shipping costs and requires stronger packaging. Heavier doors also put more strain on hinges and other hardware, leading to faster wear and potential need for higher-grade hardware—further raising costs. For these reasons, U.S. factories generally stick with MDF.

4. HDF requires more advanced machinery

HDF’s density demands more from cutting machines, causing faster tool wear, shorter blade life, longer CNC machining times, and finer, harder-to-manage dust. These “hidden costs” further increase production expenses, so many medium-to-large cabinet manufacturers ultimately choose MDF.

5. Consumers don’t know about HDF

The first four reasons are mostly industry-specific, but this one directly involves you as a consumer. Most Americans are familiar with terms like Solid Wood, Plywood, MDF, or Thermofoil, but few know what HDF is. If consumers don’t understand it, they’re unlikely to pay more for it. Even though HDF has many advantages, cabinet brands have little incentive to use it. Marketing is about selling, not educating: HDF is not flashy, cheap, or novel, and MDF already works fine. As a result, the industry quietly sticks with MDF.

6. Industry inertia

MDF has been the standard for decades. Production lines, tooling, paint systems, and packaging are all optimized for MDF. Switching to HDF would require new tools, new paint formulas, and redesigned assembly lines, which most brands consider not worth it. For consumers, HDF is almost invisible—most don’t even know it exists.

In short, HDF is stronger, denser, and more durable than MDF, but MDF strikes the best balance between performance, cost, and manufacturability. That’s why over 90% of painted Shaker cabinet doors in the U.S. still use MDF instead of HDF.

Particle Board

Particle board is made by compressing wood chips, wood shavings, and sawdust with glue under high pressure. It’s the cheapest type of engineered wood, but cabinets made from it have many drawbacks: poor load-bearing capacity, prone to breaking, can sag within 3–5 years, swells and crumbles when exposed to water, screws loosen easily, and shelves often collapse.

In my view, the only real advantage of particle board is its low cost. It’s typically used only for extremely budget-conscious cabinets, such as furniture for rental units or dorm rooms.

If you’re buying cabinets for your own home, avoid particle board at all costs. High-end—and even mainstream—U.S. cabinets almost never use particle board for cabinet boxes.

Surface Finishes

The layer you can see and touch on a cabinet is called the surface finish. It’s how the cabinet’s exterior is treated—painted, stained, laminated, thermofoiled, or veneered. The surface finish determines not only the cabinet’s look but also its durability and price. Importantly, it’s not the material itself; it’s the layer covering the core materials like solid wood, MDF, plywood, or particle board. A good surface finish makes cabinets more beautiful, durable, and moisture-resistant.

You may have come across terms like laminate cabinets, thermofoil cabinets, or veneer cabinets online. Here’s the catch—they’re not cabinet materials, but rather finishing techniques. Many buyers get confused and end up with cabinets that don’t match their expectations. Let’s break down the differences.

Laminate

Laminate comes in high-pressure (HPL) and low-pressure (LPL) types. It’s made by compressing multiple layers of resin-impregnated paper with a protective top layer. This artificial surface is then applied over MDF, HDF, plywood, or particle board. Laminate is extremely scratch-resistant, stain-resistant, water-resistant, and comes in a huge variety of colors and patterns (wood grain, stone, solid colors). It’s sleek, modern, durable, and easy to clean—perfect for contemporary kitchens.

Thermofoil

Thermofoil is a PVC film applied to MDF or HDF doors through vacuum heat pressing. Imagine wrapping a “heat-shrinkable film” around a door panel—smooth, seamless, and uniform. Thermofoil doors are stable, color-consistent, and low-cost, often used for Shaker or Slab styles, especially in whites and light grays. Unlike painted wood, they are less prone to cracking.

However, thermofoil has its downsides: prolonged exposure to high heat or steam can cause the edges to peel, and it’s less heat-resistant than laminate.

Veneer

Veneer involves slicing real wood into ultra-thin sheets (0.5–1mm) and applying them to a core material. It’s the most natural-looking surface finish. Veneer closely mimics the appearance and feel of solid wood, but is more stable and less prone to warping. Usually applied to MDF or plywood, it can have matte, semi-gloss, lacquered, or stained finishes. Veneer is commonly found in high-end modern wood kitchens or commercial cabinets, ranking above laminate and thermofoil in terms of luxury.

Laminate, thermofoil, and veneer are all surface finishes, not cabinet materials. The real cabinet materials are solid wood, plywood, MDF, HDF, and particle board—and these finishes are just the “skin” that gives them style and protection.

When shopping for cabinets, always ask yourself—are you buying the material, or just the finish? Understanding this can save you from surprises and help you get exactly what you envisioned for your kitchen. To learn more about different cabinet finishes and how they affect both style and durability, check out our detailed guide on cabinet hardware finishes.

Eco-Friendliness & Health

When choosing cabinets—especially the core materials—many people overlook a critical factor: health and environmental safety. Furniture is one of the biggest contributors to indoor air quality issues in the home, particularly when it comes to formaldehyde emissions.

Cabinets, wardrobes, and bookshelves are often made from engineered wood. To bond and stabilize these materials, manufacturers use adhesives that often contain formaldehyde. Over time, formaldehyde can off-gas into the air, and long-term exposure may affect your respiratory system and skin, ranging from mild irritation to more serious health risks.

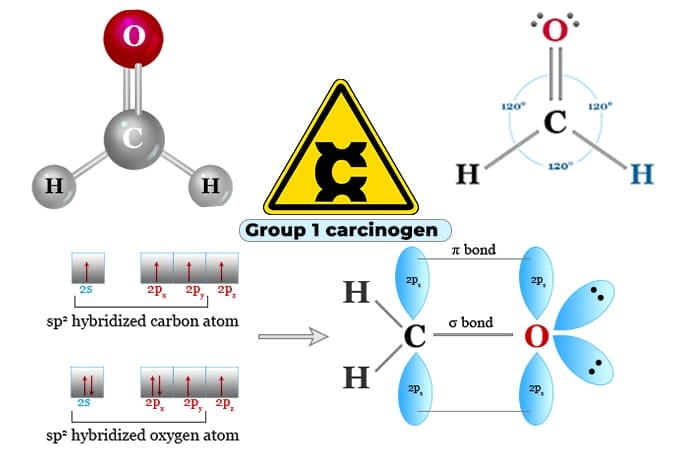

Formaldehyde is a colorless, pungent-smelling gas classified as a Group 1 carcinogen by the International Agency for Research on Cancer (IARC). This means there’s strong evidence that long-term exposure to high levels can increase the risk of cancer. This is also one reason solid wood cabinets are more expensive—they don’t use glue and therefore don’t emit formaldehyde, making them safer for long-term use.

If you care about sustainability, look for FSC or PEFC-certified wood. Many low-cost furniture pieces use non-certified boards with higher formaldehyde emissions. For your health, choose boards that comply with TSCA Title VI or CARB Phase II standards. After moving in new furniture, ventilate well, use low-VOC paints or finishes, and avoid keeping particle board furniture in constantly damp environments.

In the U.S., and especially in California, there are strict standards for formaldehyde emissions in furniture:

TSCA Title VI (EPA)

- Particle Board ≤ 0.09 ppm

- MDF ≤ 0.11 ppm

- Plywood ≤ 0.11 ppm

- HDF ≤ 0.11 ppm

Even though HDF (high-density fiberboard) is sometimes listed separately in industry guides, official regulations treat it according to its core material type (usually MDF). CARB Phase II standards are similar but stricter.

The bottom line: engineered wood furniture can release formaldehyde, but if you choose TSCA- or CARB-compliant materials, your daily exposure risk is very low.

Finding the Best Value Cabinets

Hardwood cabinets are heavy and expensive, while particle board cabinets are cheap but often low in quality. So what’s the sweet spot for most households—a cabinet that balances quality, appearance, and price?

Modern kitchens rarely rely on a single material anymore; most cabinets combine different types of boards to optimize strength, durability, and cost. The key is which materials are used where, ensuring the cabinet performs well while still offering a beautiful, affordable solution.

Take a look at RaraRTA Cabinets, designed for high value without compromising quality. A “value cabinet” can still feel premium and luxurious. Here’s an example of one of their classic Shaker-style cabinets:

- 5-piece drawer front construction

- 6-way adjustable European-style hinge with soft-close

- 5-piece birch door with veneered HDF center panel

- UV-coated natural interior

- Inset natural wood toe kick panel

- Clear coat UV finish throughout

- Adjustable 3/4″ quarter-depth shelf

- 1/2″ plywood full-height back panel

- Undermount full-extension soft-close drawer glides

- 3/4″ x 1 3/4″ solid wood cabinet face frame

- 11/16″ dovetail drawer box

- “L” bracket-reinforced base cabinets

This cabinet uses 3/4″ thick birch door frames with an HDF center panel to prevent cracking or warping. The body is made from 1/2″ plywood, and the interior features UV-coated natural wood plywood, perfectly matching the door finish. Drawers use 5/8″ solid wood dovetail construction with five-piece fronts, combined with undermount full-extension soft-close glides for smooth, durable operation. Hinges are hidden, six-way adjustable soft-close, and shelves are 3/4″ plywood. The base is reinforced with “L” brackets and 1/2″ plywood, with water-based UV finishes for durability and eco-friendliness. Toe kick panels are also 1/2″ plywood, keeping the structure consistent and stable. Many styles and colors are available.

By now, you should have a solid understanding of cabinet materials. When shopping for cabinets, don’t just pick a color you like—consider the materials too. Different materials affect durability, appearance, and health, shaping your overall kitchen experience. To see which colors are trending in 2025 and how they pair with materials, check out the top 5 kitchen cabinet colors for 2025.

Next time you browse cabinets, ask yourself: “Am I choosing the right material for my lifestyle, or just the finish?” Understanding this can save you from surprises and help you make a healthy, long-lasting choice for your home.

Add comment