No products in the cart.

Return To Shop10 Things to Know Before Ordering Custom Kitchen Cabinets

Getting cabinets right makes the whole kitchen work — get them wrong and you’ll pay for it in time, money, and headaches. This guide is written for U.S. homeowners (first-timers and experienced renovators alike). It keeps things practical and action-oriented: what to ask, what to write into the contract, and what to check on install day. Measurements show both metric and U.S. customary units for quick reference.

Table of Contents

Why this matters

Cabinets are one of the biggest-ticket items in a kitchen remodel. They involve many hidden choices — materials, construction details, pricing conventions, and add-on fees — all of which affect durability, moisture resistance, and final cost. Read this before you sign anything.

1. Custom Cabinet Pricing Explained

Many cabinet makers price by linear foot (U.S.) or linear meter depending on the company and market. If a supplier quotes “per linear meter” (common with some manufacturers that ship from overseas), confirm the baseline dimension: which height and depth are included in that price. For example, a “standard base cabinet per linear meter” usually assumes a cabinet height of ~34.5 in (88 cm) and depth of ~24 in (61 cm).

Some suppliers split pricing when a run includes only base cabinets or only wall cabinets (e.g., base cabinets might be charged at 60–70% of the standard per-meter price). Always ask: Is your quote per linear foot (or meter)? What exact heights/depths does that price cover? Are base or wall cabinets priced differently? Put the answers in writing.

2. Cabinet Panel and Countertop Thickness

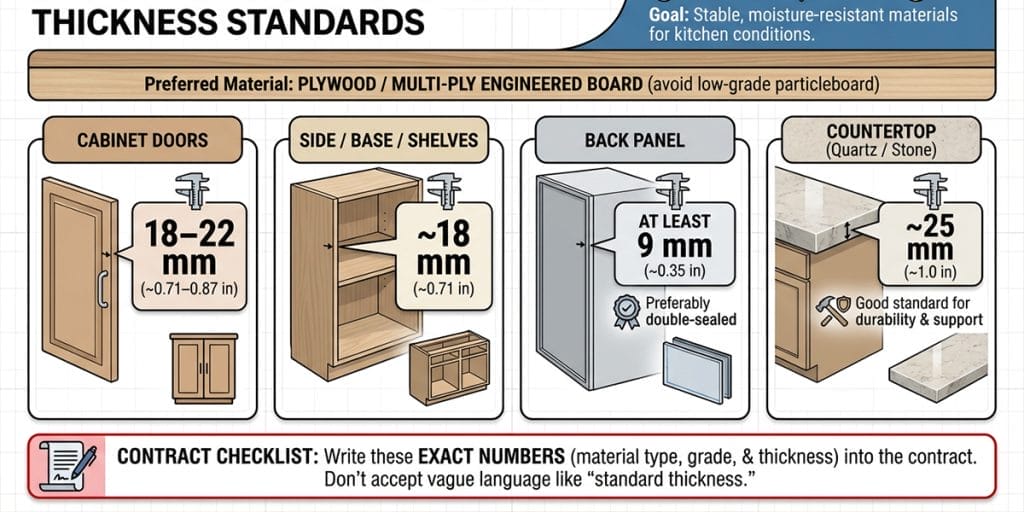

Kitchen conditions (humidity, grease, heat) demand stable, moisture-resistant materials.

- Typical cabinet structural board: plywood / multi-ply engineered board (preferred over low-grade particleboard).

- Door thickness: 18–22 mm (~0.71–0.87 in).

- Side/base/shelves: ~18 mm (~0.71 in).

- Back panel: at least 9 mm (~0.35 in), preferably double-sealed.

- Countertop: ~25 mm (~1.0 in) for quartz or stone is a good standard for durability and support.

Write these exact numbers into the contract (material type, grade, and thickness). Don’t accept vague language like “standard thickness.”

3. Back Panel Sealing and Moisture Protection

Some manufacturers only coat the visible side of the back panel to save cost. That leaves the side touching the wall raw — which can absorb moisture, warp, or emit odors. Require double-side sealing / protective finish (or sealed plywood) for any back panel that sits against a wall. Verify at delivery.

4. Extra Charges for Custom Cabinet Work

Anything out of the factory standard is extra: boxing gas lines, building soffits, angled cuts, curved cabinets, or irregular filler pieces. Ask for a written line-item price for each nonstandard operation before signing. Example contract item: “Pipe box (per linear foot): $XX; angled end panel (per corner): $YY.” This stops surprises at install.

5. Sink Base Cabinet Moisture Protection

The sink area sees the most moisture. Options:

- Best: stainless steel liner for the sink base.

- Budget-friendly: heavy-duty aluminum foil / waterproof liner.

- Don’t let the cabinet sit directly on the floor. A plinth/hidden toe-kick of about 10 cm (≈4 in) reduces splash contact and avoids water creeping into the cabinet bottom.

Put the sink base protection method and toe-kick height in the contract.

6. Single vs. Multi-Level Countertop Heights

Two countertop heights can improve ergonomics (e.g., a lower prep surface, higher bar), but they:

- Raise fabrication difficulty and cost,

- Reduce continuous usable counter area, and

- Create joints where crumbs/dirt collect.

If you prefer low maintenance or have a compact kitchen, choose a single standard height. If ergonomics are a priority, plan for careful detailing and waterproof joint treatment where heights change.

7. Countertop Support and Load-Bearing

Countertops need support under heavy use. Options:

- Full support board under the countertop (best for heavy stone and to avoid flexing).

- Support strips (3–4 strips across the span) — often plastic or metal. Avoid wood-only supports in moist locations (wood swells).

- If you plan heavy chopping or place heavy appliances on the counter, require full support under the contract.

Specify support type and material in writing.

8. Cabinet Hardware: What’s Included

Many quotes exclude hardware (handles, soft-close slides, pull-out baskets). Before you sign:

- Get brand names and model numbers for slides, hinges, and pull-outs.

- Specify quantities and exact locations.

- If you’ll buy hardware yourself, confirm the installation fee (or that installation is free).

- For warranty reasons, note whether manufacturer warranties remain valid if you supply your own hardware.

Add an explicit “hardware included” section to the contract listing brands and counts.

9. After-Sales Service and Warranty

Price is important — but so is who’s behind the product when something goes wrong. Local shops often offer quick, personal service but short warranties; larger companies may offer longer warranties and multiple warehouses for replacements.

If you pick a factory-direct or online brand, check shipping/lead times and warehouse coverage. For example, some nationwide RTA/pre-assembled suppliers advertise multiple U.S. warehouses and fast shipping options; they also publish comparisons of RTA vs. pre-assembled timelines and pros/cons. If you plan to order from such a supplier, confirm warranty length, how to file a claim, and average response times, and ask for references or sample doors.

10. RTA vs. Pre-Assembled Kitchen Cabinets

- RTA (Ready-to-Assemble): cheaper, ships flat, good for DIY or if you want lower price and can handle (or hire) assembly. Faster shipping for some lines, but assembly time & skill matter.

- Pre-assembled: more expensive but faster to install on site and less dependent on installer skill. Good if you want a quicker, lower-risk install.

Some vendors sell both options and provide clear comparisons of cost, shipping, and assembly tradeoffs — review those guides before deciding.

Downloadable Cabinet Contract & Installation Checklists

Get both the Contract Checklist and the On-Site Cabinet Installation Checklist in one downloadable file.

These checklists include contract-ready clauses and install-day inspection points to help you avoid costly mistakes before final payment.

The complete table, including copy-and-paste short contract clause templates, is available for download:

Contract and Installation Checklist (Download)

Includes both the Contract Checklist and the On-Site Cabinet Installation Checklist, with copy-and-paste clause templates ready to use in your cabinet purchase agreement.

Download Checklist (Excel)Frequently Asked Questions (FAQ)

Are RTA cabinets low quality?

Not necessarily. RTA saves money by shipping flat — material quality varies by brand. Look at plywood grades, hardware brands, and whether the factory uses dovetail drawers and full-extension soft-close slides.

How thick should my countertops be?

Around 25 mm (~1 in) is common for quartz and stone. Thicker slabs cost more and may need stronger supports.

Can I order samples?

Always request a sample door and edge sample before final production. Many national suppliers will ship samples for a small fee or free; confirm the policy first.

Who installs RTA cabinets?

RTA requires either DIY assembly or a local pro. If you lack a reliable installer, pre-assembled may be a safer option.

Final Checklist Before You Sign

| Check Item | What to Confirm |

|---|---|

| Pricing units | Confirm whether prices are quoted per linear foot or per meter, and convert them to compare apples-to-apples. |

| Extra charges | Make sure all extras are clearly priced and written into the contract. If it’s not in the contract, it’s not included. |

| Samples & finish | Request sample doors and verify the finish under your actual kitchen lighting. |

| Warranty & after-sales | Confirm warranty coverage, service responsibilities, and response time for repairs or replacements. |

| Installation inspection | Keep an install-day checklist and photograph any defects before final acceptance. |

Closing Notes

Good cabinets make daily life easier — they should be planned deliberately, not rushed or left to vague promises. Use the contract checklist above, insist on documented specifications, and don’t sign until your sample matches your expectations.

If you’re exploring factory-direct or nationwide RTA/pre-assembled brands, RaraRTAcabinets is an example of a supplier that sells both RTA and pre-assembled cabinets, offers fast shipping and multiple U.S. warehouses, and publishes helpful guides comparing the two formats. Check shipping timelines, sample policies, and warranty terms on their site before deciding.

Add comment