No products in the cart.

Return To ShopHow to Choose Kitchen Cabinets for Humid Climates

Living in Florida, the U.S. Southeast, Hawaii, or any tropical/coastal zone means humidity isn’t just an annoyance — it’s a design factor you must plan for. Make the wrong choices and your “new” kitchen could show swollen cabinet edges, rusty hardware, black mold, and costly repairs within a few years.

This guide translates ten years of hands-on experience in Hawaii into clear, actionable advice: what materials to choose, what details to demand from your cabinet maker, and small design choices that prevent big headaches later. Read on for material comparisons, suggested specifications, a contractor checklist, and an FAQ to help you renovate with confidence.

Table of Contents

Quick summary: the most important rules

- Cabinet boxes: prefer HDF (high-density fiberboard) or quality marine-grade plywood; avoid low-grade particleboard in wet zones.

- Edge banding & surface finish: must be thick and professionally applied; sealed on both sides.

- Hardware: use stainless steel (304 for general, 316 for coastal/salt air). Choose reputable brands and thick, solid components.

- Countertops: choose water-resistant materials (quartz, stainless steel) and add a water-blocking strip where the counter meets the wall.

- Sink: undermount sinks reduce standing water and make cleaning simpler.

- Ventilation: ventilated cabinet doors or intentional vent holes for the sink cabinet reduce trapped humidity.

- Small helpers: desiccants (silica gel), bamboo charcoal packs, and good airflow help but don’t replace material and design choices.

1. Cabinet box material: why HDF?

HDF = High-Density Fiberboard. It’s an engineered wood panel made from wood fibers compressed at high pressure. In humid climates you want low swelling, dimensional stability, and a surface that can be well sealed.

How common options compare

| Material | Pros | Cons | Use in humid climates? |

|---|---|---|---|

| HDF (High-Density Fiberboard) | Dense, stable, smooth surface; better swelling resistance than low-grade particleboard | Needs good surface sealing and edge banding | Recommended for cabinets if properly sealed |

| Particleboard (standard) | Low cost | Absorbs moisture quickly; swells and crumbles at edges | Not recommended near water or in humid regions |

| MDF | Smooth finish, good for painted doors | Higher water absorption than HDF; swells when wet | Use only for non-wet areas / painted doors with strong sealing |

| Plywood (good grade) | Strong, holds screws well; good moisture performance if marine or exterior grade | More expensive; quality varies | Good option — choose quality plywood (exterior/AB grade) for humid areas |

| Marine-grade plywood | Excellent moisture resistance | Higher cost | Best where budget allows (under sinks, open shelving) |

Recommended cabinet box thickness: 15–18 mm (approx. 0.6–0.7 inches) is common. Use thicker 18 mm for base cabinets that carry heavy loads (appliances, countertops).

Edge banding: pick edge banding that’s at least 0.5–1.5 mm thick and bonded with a quality adhesive. If the workshop uses thin/brittle tape, moisture will creep in over time.

2. Surface Sealing: Don’t Skip It

Even the best core material fails without proper sealing.

- Ask for double-sided sealing (both inside and outside of the board) so the panel absorbs moisture evenly.

- Prefer melamine or PVC laminated finishes with treated paper and a good factory seal.

- For painted surfaces, insist on a primer + topcoat and sealed edges.

- Use silicone or polyurethane at cabinet joints where water might enter (e.g., under sinks, backsplash joints).

3. Hardware 101: Pick the Right Stainless Grade

Hardware corrodes faster in salty, humid air. Choose both reputable brands and the right steel grade.

- 304 stainless steel: Very common, good corrosion resistance for most indoor kitchens.

- 316 stainless steel: Contains molybdenum for superior corrosion resistance — recommended for coastal homes or heavy salt exposure.

Also look for: soft-close hinges and drawers from well-known brands, full-extension undermount slides, and thicker gauge metal (feels solid, not flimsy).

4. Best Countertops for Wet Areas

The countertop is the bridge between wall and base cabinets — get it wrong and water will collect and seep.

Good choices:

- Quartz (engineered stone): Non-porous, resists stains and water.

- Stainless steel: Completely non-porous and easy to clean; excellent for heavy-use kitchens.

- Solid surface (e.g., Corian): Seamless options available; good resistance but seams must be professionally installed.

Avoid: porous natural stone (e.g., untreated marble) unless it’s properly sealed and maintained.

5. Water-Blocking Strips & Counter Details

Small details prevent big problems.

- Install a water-blocking strip (backsplash skirt) along the back edge where counter meets wall. It directs water back onto the counter and away from the cabinet seam.

- Consider a front lip if you want to protect clothing and small items.

- Design a drainage slope in the countertop profile so spilled water flows toward the sink rather than pooling.

6. Undermount Sinks — Cleaner, Drier Edges

Top-mount sinks trap food and water on the rim, which can lead to mold. Undermount sinks create a flat, wipeable transition from counter to sink. This reduces standing water and keeps the rim area drier and easier to maintain.

If you must use a top-mount sink, insist on excellent sealing with sanitary silicone and regular maintenance.

7. Venting Your Cabinets to Prevent Mold

The plumbing cabinet under the sink stays damp. You can:

- Use vented or slatted doors to allow passive airflow.

- Cut a discreet vent hole in the back panel (covered with a grille) to encourage cross-flow.

- Keep the area under the sink clean and periodically open the doors to air it out.

8. Charcoal, Silica & Dehumidifiers — What Helps

Portable solutions help but don’t replace correct materials.

- Bamboo charcoal packs: natural, absorb odors and some moisture.

- Silica gel or rechargeable desiccant boxes: good for cupboard interiors.

- Dehumidifier or good HVAC system: the best way to control home humidity at scale.

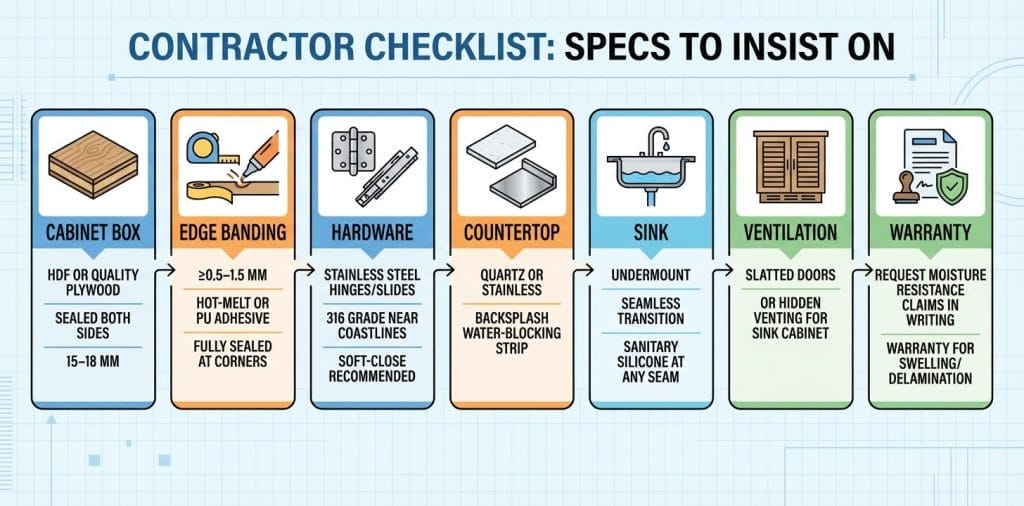

Contractor Checklist: Specs to Insist On

- Cabinet box: HDF or quality plywood, sealed both sides, 15–18 mm.

- Edge banding: ≥0.5–1.5 mm, hot-melt or PU adhesive, fully sealed at corners.

- Hardware: stainless steel hinges/slides; 316 grade near coastlines. Soft-close recommended.

- Countertop: quartz or stainless; include backsplash water-blocking strip.

- Sink: undermount with seamless transition; sanitary silicone at any seam.

- Ventilation: slatted doors or hidden venting for sink cabinet.

- Warranty: request moisture resistance claims in writing (e.g., warranty for swelling/delamination).

FAQ: Quick Answers

Is HDF waterproof?

No engineered wood is truly waterproof. HDF is more moisture-resistant and stable than cheap particleboard, but it must be properly sealed and protected.

Can I seal particleboard to make it usable in humid areas?

Sealing helps but does not fully eliminate the risk. If budget allows, upgrade to HDF or plywood for wet zones.

What stainless grade should I choose for hardware near the ocean?

316 stainless is the safest choice for heavy salt exposure. For non-coastal humid areas, 304 is generally sufficient.

Will caulking and silicone fix all leaks?

Sealants reduce risk but don’t replace material choice and design. Proper construction details and periodic maintenance are still necessary.

Final Tips

Humidity is manageable with the right choices. Spend your renovation budget first on material quality and proper sealing, and then on convenience features like good hardware and undermount sinks. Small investments up front (better core panels, thicker edge banding, 316 hardware near the coast) pay off as years of trouble-free use.

Add comment